A collection of bio-sourced, recycled and recyclable materials that help to reduce the environmental impact of products.

PA11 by Materialise

SILMO Next: MATERIALISE

Polyamide 11 is a nylon bioplastic, derived from a renewable source of castor beans. Used in the 3D printing process, Selective Laser Sintering, PA11 offers a versatile option for the creation of lightweight, durable and flexible frames in a sustainable material. High strength and high impact resistance ensure optimum performance while allowing for the creation of intricate and streamlined shapes.

An off-white material in its raw state, PA11 is well-suited for post-processing and color treatments, to offer an extensive choice of surface finishes and colors. An array of colors can be realized with bespoke color creation to produce a beautiful frame with a premium look and feel.

Verres Divel

SILMO Next : DIVEL

In response to market demand, Divel Italia, in addition to reducing the environmental impact of our production site, now produces lenses and solar filters using increasing percentages of organic materials and environmentally sustainable by-products.

After the various experiments and other projects in 2019 concerning lens waste, which focused post-production disposal, Divel Italia has finally launched the environmentally sustainable lens.

GREEN LINE lenses include 39% resins of plant origin, with the remainder being fossil-origin by-products. Not only have we reduced the use of fossil-origin by-products compared to normal lenses, we have also reduced the environmental impact of production.

Highlight, lighting made from rejected lenses

Every year, thousands of lenses that don’t meet quality standards are thrown away. How can we make use? Divel, working with third-year students of Industrial Design, coordinated by professor Dario Russo at the University of Palermo, has come up with an answer. These students, assisted by designers Federica Ditta and Cristiano Pesca, analyzed how the lenses interact with light and the characteristics of that light, including the generation of phenomena like rainbows, caustics, backscatter, and aurora. After this, they sought to reproduce these effects by having the lenses interact with sources of light. This gave rise to the Highlight line of lighting products—including floor lamps, table lamps, ceiling and wall lamps—that reproduce these optical effects.

Fossili: display cases

With the help of smart, dynamic experts, our studies of lens recycling and reuse have led to applications in packaging, interior design, and even exhibition furnishings! Federica Ditta and Cristiano Pesca designed two display pedestals: the key feature of these pedestals is that they, too, make use of reclaimed lens waste! Designed to support display cases in exhibition spaces, our ECO-EXPO pedestal is made from a sheet of carbon steel and an epoxy-resin panel with lens fragments. Federica and Cristiano also worked with Divel to design and create our exclusive lens sample cases!

« EYE OF THE FUTURE », by Emanuela BERGONZONI

Out of a shared interest in environmental sustainability came an opportunity for Emanuela to take a look at defective lenses discarded by Divel in an attempt to figure out how they could be used to create objects of design. Inspired by Divel’s Green Line project and by her experiments with this material that was so new to her, this talented designer came up with her work “Eyes of the Future” by bringing art to eyewear design. The work looks to a future that is totally submersed in plastic, as reflected in the glasses that block the wearer’s view. This eyewear is purposely designed to be dangerously sharp so as to underscore the hazard of waste and of plastic. But all is not lost. By activating the third eye, and with the wisdom that results, we can imagine a future rich in virtuous behavior—reduction, reuse, recycling, and reclamation.

Charnières OBE

SILMO Next Talks — OBE

Ecological production since 1996

- 80% waste reduction

- 30% reduction in energy consumption

- 65% reduction in water consumption

- 60% recycled material in frames and flex boxes made in Germany

- Plastic cores used for hinge screws are 100% recycled

Flexuno Mini - The more ecological flex

- 25% less material than other flex

- 0% nickel surface treatment on reinforcements

- use of 100% recycled stainless steel

- medical stainless steel without nickel discount

Silcon Plastic biopolymers

SILMO Next Talks — SILCON PLASTIC

What is Bioline ?

Bioline is Silcon Plastic’s line of green materials. A selection of biopolymers from the best manufacturers to satisfy the requirements of all customers.

Why Bioline?

- materials from totally or partially renewable sources

- strong reduction of CO2 emissions

- compostable or biodegradable

- all recyclable

- wide range of aesthetic properties

- wide range of mechanical properties

- wide range of colors available

- non-toxic

Typologies and characteristics

- BIOLINE A: 58% natural source, recyclable and transparent

- BIOLINE B: almost 100% natural source and recyclable

- BIOLINE C: 100% natural source, recyclable and compostable

Lasertech laser cut

50 years in etching excellence and laser cut pioneer

Using recycled metal materials requires adapted technologies. It is necessary to have a critical size to be able to supply these materials.

Lasertech offers small creators the opportunity to have access to these materials, by purchasing raw material in large quantities, and by manufacturing mini-series in a very flexible manner. Lasertech’s experience and multi-sector activity allows eyewear manufacturers to have access to new materials developed for other industrial sectors.

Recyc Leather material

SILMO Next Talks — RECYC LEATHER

Recyc Leather recycles leather scraps from industrial glove factories.

Our material is produced from leather scraps, collected from factories manufacturing garden gloves in South China. Too small to be reused, these scraps were destined for destruction. Recyc Leather has found a way to recycle them by giving them a second life. As soft as traditional leather, recycled leather is ideal for leather goods.

A sustainable circle to genuine leather

- 100% Natural Recycled Material (Fibers + Latex + Water)

- 20 Tons Wastage Saved (Going to Landfill)

- 90% Use Less Water (from Traditional Tannery)

- Zero Manufacturing Waste (Recycle our factory’s off-cuts)

Recyc Leather is proud to be qualified to the

United Nations Sustainable Development, Goal #12, Responsible Consumption & Production.

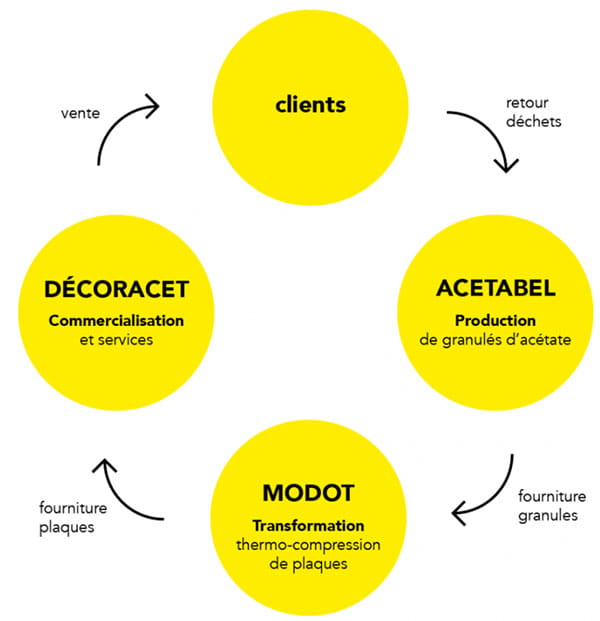

Décoracet acetate

100% French Acetate

Recycling : what if your trash was brought to light?

- WASTE SORTING AND COLLECTION Waste from manufacturing of your acetate frames are sorted, by you, according to their nature (acetate exclusively) and in a concern of creation of colors.

- WASTE TREATMENT At its Bellignat site, Décoracet crushes and then screens your waste to transform it into acetate granules.

- THERMOCOMPRESSION Acetate granules are thermo-compressed at Modot to produce a single sheet from your own waste.

- MACHINING OF EYEGLASSES Your eyewear craftsmen shape the frames imagined by your designers in this inimitable new plate.

Circular economy

Material origin: hydrocarbons / bio-sourced : Fossil” or petroleum-based materials contain phthalates and bisphenols, which are endocrine disruptors said to be responsible for diseases. A “bio-sourced” material owes its origin to a “renewable” material derived from the bio-mass (plant, living organism).

Recyclable plastics: Recycling is a process of reintroducing materials into a new production cycle. We have “thermoplastics” which are recyclable plastic materials and “thermosetting” which are non-recyclable.

Degradable plastics: A degradable material is altered by the action of bacteria or by oxygen (breaking of the molecular chain). The “biodegradability” of a material is its ability to degrade by the action of biological organisms, and to be transformed into carbon. It is said that a material can be biodegradable in a saline, compost, or aerial environment.

ACETABEL

Décoracet is committed to the CIRCULAR ECONOMY: The recovered waste is crushed and then transformed, by an extrusion process, into acetate granules for the injection of plastic parts or thermocompression at Modot, of which it is the main supplier.

MODOT

- Manufacture of acetate sheets from thermo-compressed granules

- Wide choice of colors and shades: transparent, translucent, opaque, pearlescent, iridescent, etc.

- Possibility of personalized creations

DECORACET

ACETATE PLATES:

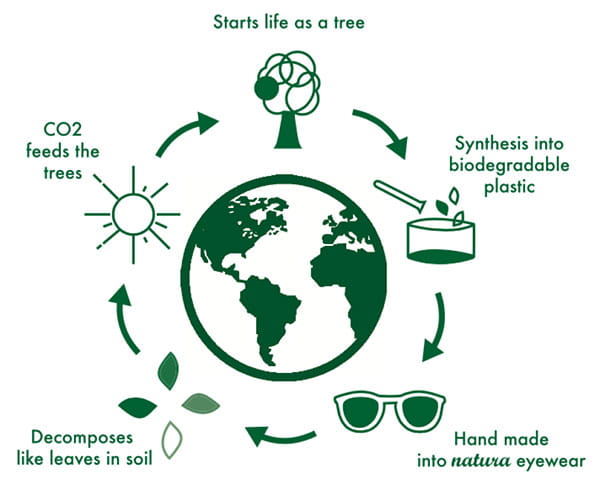

KILLINE biodegredable acetate

SILMO Next Talks — KILLINE

“Go green today with KILLINE”

Choose a vision of the future: For well over 15 years, KILLINE has been a pioneer of the eco-friendly move in the optical industry. We mean to maintain our leadership based on inventivity and the conviction that

«you don’t have to sacrifice either performance or price to make a positive environmental impact».

Our technology: Eco-acetate is a compostable thermoplastic based on Cellulose Diacetate, from vegetal cellulose. It works exactly the same way as acetate and can be used for handmade frames.

Biodegradable (certified ISO 14855): Biodegradation is the chemical breakdown of material by environment. Biodegradable plastic will decompose «the same way a tree leaf does»…

Shelter wood

Shelter is a brand making wood and metal glasses, handcrafted in France.

SILMO Next Talks — SHELTER

ARKEMA Rilsan® Clear polyamide

ARKEMA Rilsan® G850 & G820, a biobased nylon injection alternative.

The two Rilsan® products are rigid materials, offering a biobased alternative to your Nylon injections.

Not just « bio-based »

- The highest performing polyamide range

- Biobased, Renewable, low carbon footprint vs LCPA

- No competition with food, no deforestation

- Profitable crop, sustainable farming

- Recyclable; Open-loop, Closed-loop

ARKEMA Rilsan® Clear G850

- hardness 1600 — nylon type

- Contains 45% bio-based carbon according to ASTM D6866

This product is a high performance transparent copolyamide, partially based on renewable resources. This grade has been especially designed for injection molding applications, ideally suited for optic as high end eyewear frames. 46% made from castor oil, and a petrol substance for the non-biobased part. This product is also BPA free.

Comparable to TR90 (hardness 1600)

ARKEMA Rilsan® Clear G820

- hardness 1500 — nylon type

- Contains 65% bio-based carbon according to ASTM D6866

This product is a high performance transparent polyamide with outstanding chemical resistance and stress cracking resistance. This grade has been designed for injection molding applications. This one is a bit softer than G850, suitable for double injection. 65% made from castor oil, and a petrol substance for the non-biobased part. This product is also BPA free.

Comparable to TR90 LXS

Eastman acetate

SILMO Next Talks — EASTMAN

Eastman Acetate Renew: fully sustainable Acetate

With growing consumer demand for sustainable eyewear and few high-performance solutions, eyewear designers are frequently forced to make a choice between sustainability and style. Eastman Acetate Renew, made through Eastman’s innovative Carbon Renewal Technology, enables sustainable eyewear without compromising on style or functionality.

Eastman Acetate Renew brings three key benefits.

- Fully sustainable product with lower carbon footprint: meets consumers’ demand for sustainable fashion

- Identical Performance: unlike many sustainable alternatives, Acetate Renew has the identical look and feel of first-generation acetate

- Landfill avoidance: Made from waste plastic that would otherwise end up in landfill, or worse.

Eastman’s Acetate Renew is a cellulose diacetate composed of 60% biobased and 40% certified recycled content. Thanks to the unique Carbon Renewal Technology, Acetate Renew, offers virgin-material performance as well as a 20-50% reduction in greenhouse gases when compared to traditional acetate flake.

Acetate Renew is already available in sheet form from Mazzucchelli 1849 in China and Italy, with other companies to start offering soon.

Contact: Ms Rachel Oakley - Eastman Chemical, Tel +31 10 2402 111

Lucal materials

Recycled carbon material

This material comes from the revalorization of carbon fiber scraps from the French aeronautics industry. Indeed, we collect roll ends and cuttings from the aeronautics industry, to produce new light resistant plates, with a classic or random raster pattern. We thus avoid incinerating or burying original raw materials, of high quality, but not transformable by the aeronautics industry (small scraps). Thanks to a process of sorting, calibrating and manual assembly of the scraps, we can produce resistant, quality parts from secondary raw material, thus prolonging its lifespan. The material, which is fired under pressure, can be moulded into shape and then cut with a water jet. It is also guaranteed French origin.

Bio-sourced plastic

This bio-sourced injectable plastic material is produced in France. Its base being white, it can be colored in the mass. Its satin aspect and soft to the touch is characteristic of this material. The production tests showed us that the material was sufficiently deformable and with shape memory to forcefully eject a front face without any particular movement in the mold at the level of the lens straps. The temples can also be heated by the optician to adjust to the wearers of glasses (we advise to arm them in order to keep the shape over time). Unframed temples can be produced if the parts are curved to fit the shape of the head. The material is soft and comfortable to wear. Finally, this material is recyclable.

Recycled plastics

We offer different types of plastic from waste recycling. For example, we can produce calibrated sheets of 6 mm thickness or more, which can be machined and thermoformed, in PET, from the reuse of water bottles and other food packaging waste. We also offer a polycarbonate-based material from the recycling of CDs and DVDs. We can also formulate and produce sheets from your own waste. Different injection and thermocompression processes can be used to produce the plates, with special profiles, for example, to produce plates with variable thickness.

Fellow Earthlings acetate

Fellow Earthlings is a handmade eyewear company based on Prince Edward Island. Specializing in design, prototyping, and custom handmade eyewear, with a focus on sustainable manufacturing.

Taking responsiblity for our waste footprint as a manufacturer, Fellow Earthlings has developed an exclusive in-house acetate recycling program reprocessing would-be waste material in a traditional manufacturing environment into 1/1 acetate frames. The RE:FE recycled acetate frame collection is our comittment to sustainability and creativity, bringing the first premium recycled acetate product to the industry. The quality and beauty of the product leaves no compromise for an elevated sustainable option.